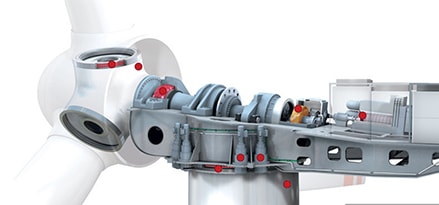

Lubricants for wind turbines

-

Mobil SHC™ Gear 320 WindPower

Endorsed by DNV for its fill-for-life capability. Mobil SHC Gear 320 WindPower proprietary technology and in-service solutions are designed to protect gearboxes, maintain excellent performance in all conditions, optimize uptime, reduce maintenance costs, and enhance safety throughout the gearbox’s lifetime.

-

Mobil SHC Gear 320 WT

Synthetic wind turbine gear oil that help extend equipment life, independently certified to not contribute to oil related effects of white etching cracks.

-

Mobilgear SHC™ XMP 320

Advanced wind turbine gear oil formulated to provide excellent wear protection and deposit control for long gear and bearing life.

-

Mobil Flush 320

Flushing oil for wind turbine gearbox systems when the intention is to change any incumbent wind turbine gear oil to Mobil SHC™ Gear 320 WT

-

Mobil Xtra™ YMP WT

Mobil Xtra™ YMP WT is a top treat product which helps extend oil life of current Mobilgear™ SHC XMP 320 oil charge should the maintenance schedule go beyond its warranty period of 5 years.

-

Mobil SHC™ Grease 681 WT

Synthetic wind turbine grease for yaw, pitch and main bearing with outstanding low temperature properties.

-

Mobil SHC™ Grease 460 WT

High performance synthetic grease for wind turbines that also retains excellent performance in hostile aqueous environment.

-

Mobil SHC™ Grease 461 WT

Synthetic wind turbine grease for yaw, pitch and main bearing with outstanding low temperature properties.

-

Mobil SHC™ Grease 68 IPC

Specially designed to exceed the demanding requirements of wind turbine individual pitch control bearings that do not complete full rotations at extreme temperatures.

The white etching cracking phenomenon: how to minimise it and keep your wind turbines turning

Technical and useful resources

Find technical solutions, service expertise and quick tips for all your wind turbines.

Mobil SHC™ Gear 320 WT is proven to not contribute to the oil-related effects of white etching cracks (WEC)

With 60 per cent of wind turbine gearbox failures attributed to WEC, it is a serious issue for wind turbine operators that can result in costly maintenance and lost productivity

Wind turbine flushing and filtration services

This service facilitates trouble-free gearbox flushing and filtration to optimize turbine reliability

How to improve safety in wind turbine maintenance

Wind turbines are particularly challenging to maintain, given the tight quarters and great heights of the gearboxes. So, what can operators do to reduce the safety risks associated with wind turbine maintenance?

Services that advance your business

We have expert knowledge to support you every step of the way with your equipment servicing requirements.