High velocity oil flushing

Lube system flushing and filtration, when done properly by a trained engineer, can help you boost equipment reliability and avoid costly downtime due to carbon and/or varnish/sludge buildup.

Description

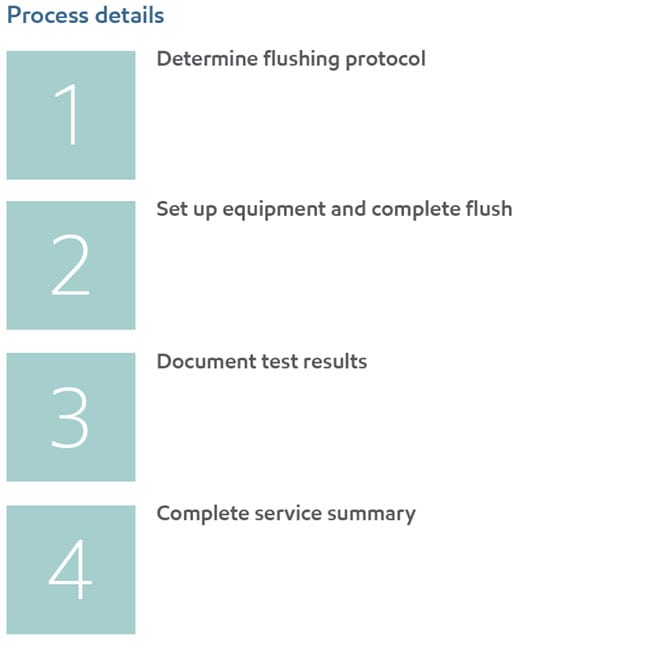

Expert engineers thoroughly inspect your equipment to assess the cleanliness of your lubricant circulation system. If necessary, they recommend a high-velocity oil flush to remove carbon and/or varnish/sludge buildup that can severely compromise equipment performance.

Application

Expert engineers will work with you to:

- Implement a plan to ensure optimal equipment performance

- Help achieve the recommended cleanliness level

- Coordinate with service provider to:

- Complete the high-velocity oil flush

- Gather baseline and other relevant data

Deliverable: An Engineering Service Report details the treatment steps completed, documents the fluid cleanliness prior to and after treatment, recommends steps to maintain cleanliness and provides an estimated value of the service. Distribute and present the completed report to plant management and key personnel.

Common opportunity areas

- Restricted orifices impeding flow

- Varnish/sludge buildup

- ISO cleanliness not meeting original equipment manufacturer specifications

- Frequent component failures due to lubricant contamination

Safety, health and environment

Field engineers are attuned to the hazards of handling, storing and using petroleum products. They strictly observe safety and environmental rules and ExxonMobil and customer safety practices. They coordinate efforts through designated plant personnel verifying electrical and mechanical lockout and proper tagging prior to working on equipment, and providing recommendations to help reduce hazards.