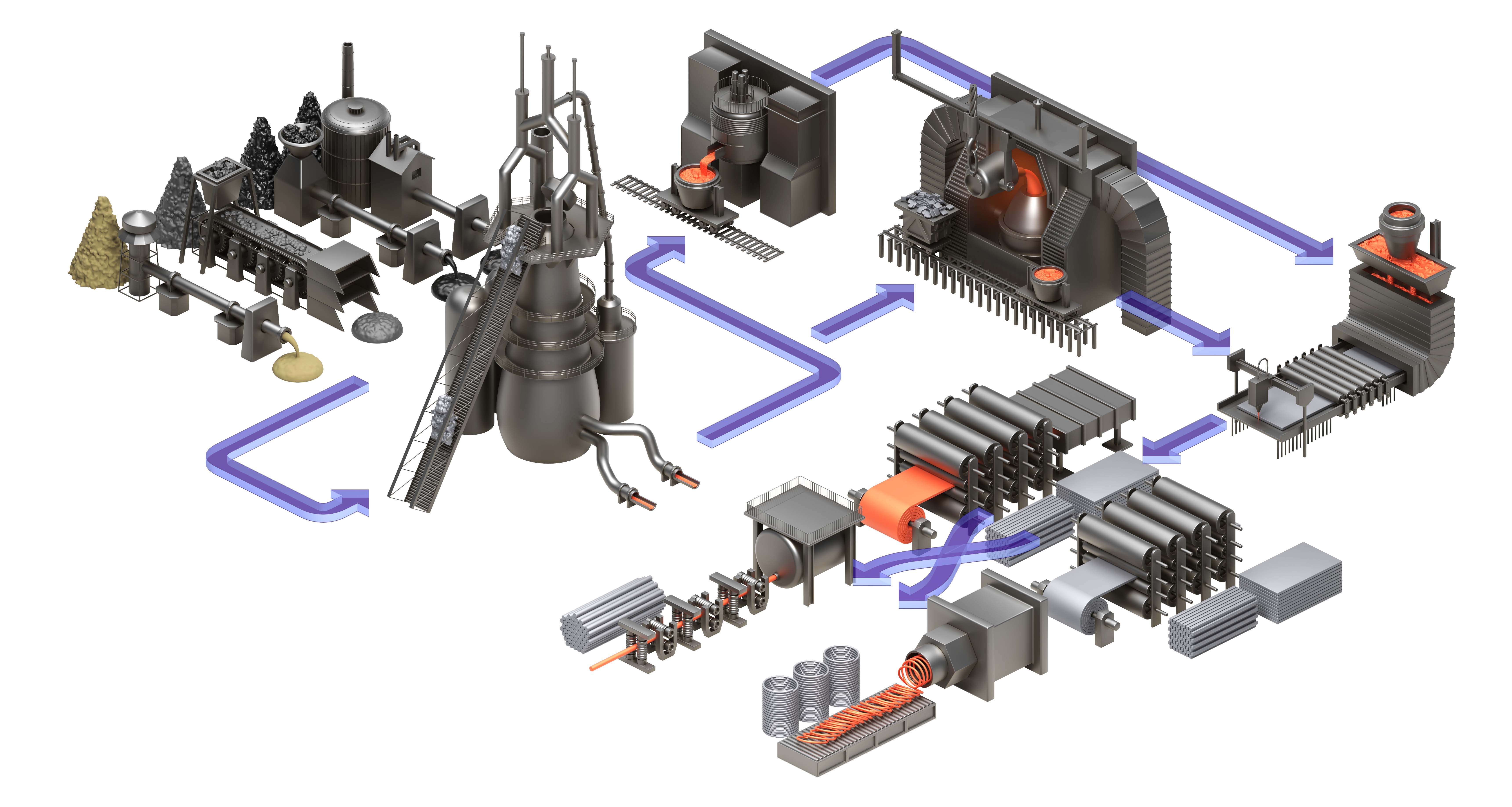

Steel production

Explore equipment and application specific to your industry in the below schematic. You can click on the hotspots in the schematic or on items in the right-hand equipment menu to see corresponding lubricant information. You can then click on a specific lubricant to see more detail about that product.

Equipment

Close

01. Material handling

View Products02. Blast furnace

View Products03. Electric arc furnace (EAF)

View Products04. Basic oxygen furnace (BOF)

View Products05. Continuous casting

View Products06. Hot rolling

View Products07. Cold rolling

View Products08. Bar rod rolling

View Products09. Wire rod rolling

View Products01. Material handling

Preparation and transfer of iron ore, coke, limestone, and scrap ensure consistent feedstock quality and controlled furnace charging.

View the Material Handling

View the Material Handling

02. Blast furnace

Iron ore is reduced using coke and fluxes at high temperatures, producing molten iron, with slag formed as a by-product.

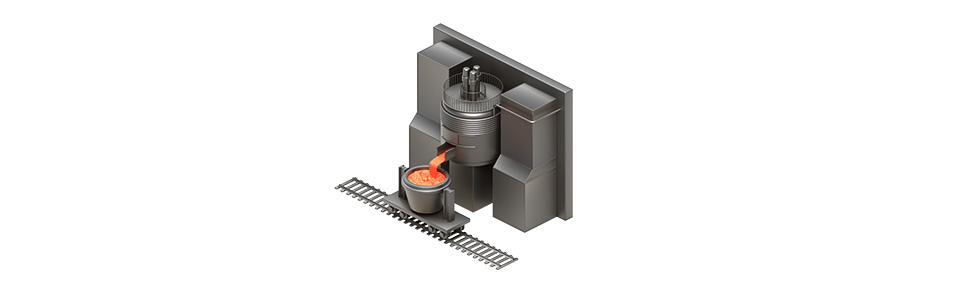

03. Electric arc furnace (EAF)

An electric current melts scrap steel or direct reduced iron, offering flexible, energy-efficient steelmaking with precise control over chemistry.

View the Electric Arc Furnace

View the Electric Arc Furnace

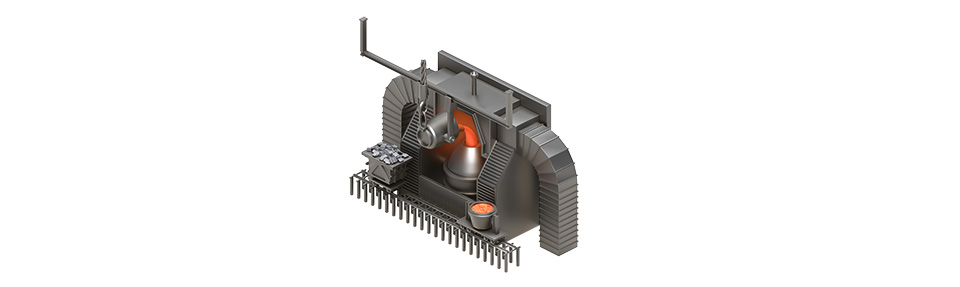

04. Basic oxygen furnace (BOF)

High-purity oxygen is blown into molten iron and scrap to rapidly lower carbon levels, refining the hot metal into crude steel.

View the Basic Oxygen Furnace

View the Basic Oxygen Furnace

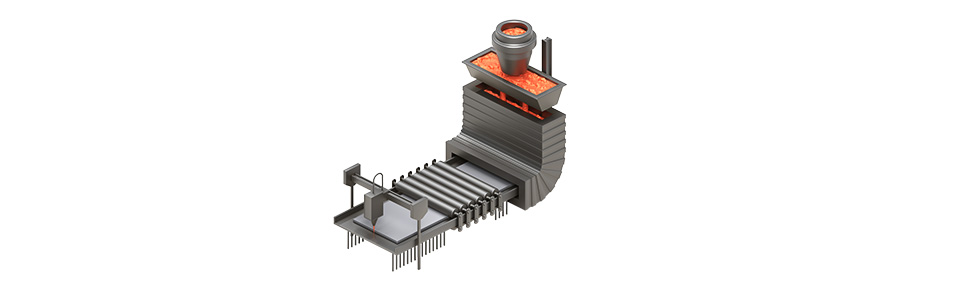

05. Continuous casting

Molten steel is solidified into semi-finished billets, blooms, or slabs through water-cooled moulds, improving yield and energy efficiency compared to ingot casting.

View Continuous casting

View Continuous casting

06. Hot rolling

Reheated slabs are rolled at 1,200°C to reduce thickness and form semi-finished products such as coils, plates, and blooms.

View the Hot Rolling

View the Hot Rolling

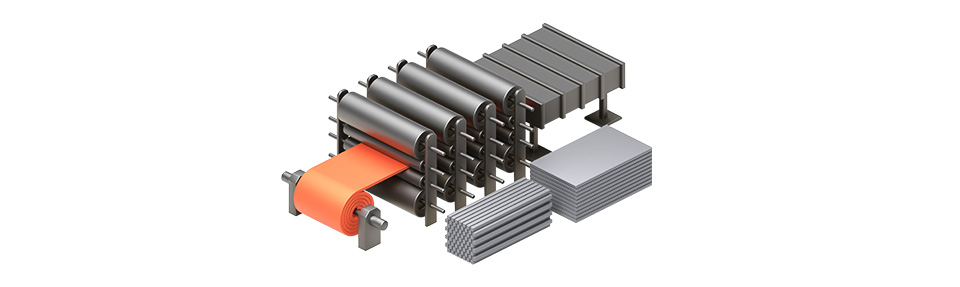

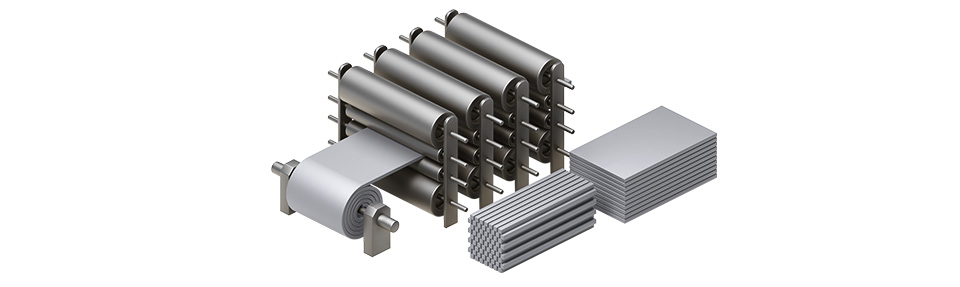

07. Cold rolling

Steel coils are processed at ambient or moderate temperature for improved surface finish, tighter dimensional tolerances, and work-hardening.

View the Cold Rolling

View the Cold Rolling

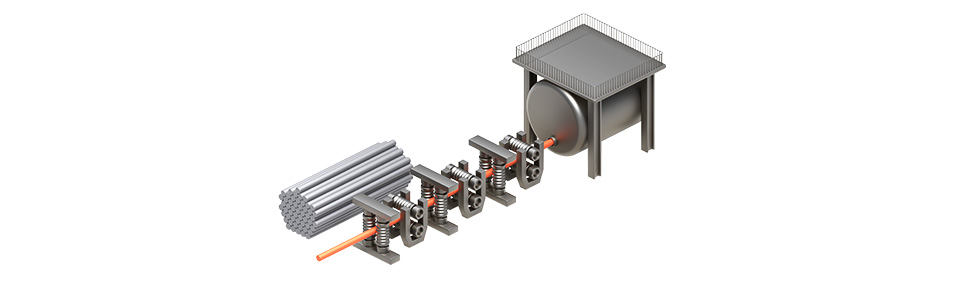

08. Bar rod rolling

Heated billets are rolled into bars of precise cross-section and strength, used for construction reinforcement and engineering applications.

View the Bar Rod Rolling

View the Bar Rod Rolling

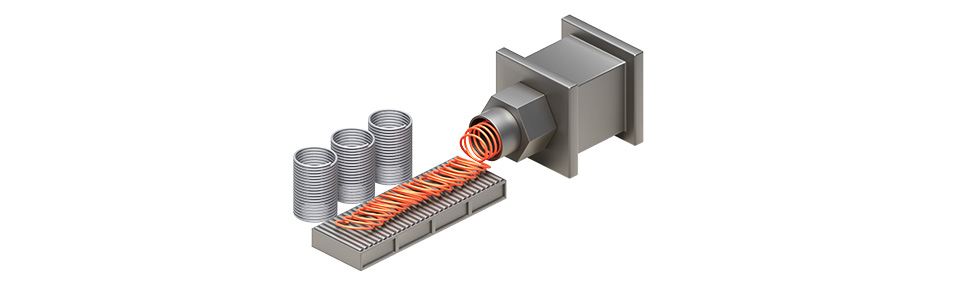

09. Wire rod rolling

Billets are rolled through continuous stands to produce wire rods with controlled diameter, mechanical properties, and surface quality.

View the Wire Rod Rolling

View the Wire Rod Rolling

Note: Schematic and product recommendations are intended as a general guide only. Products listed are the product series names. Please refer to equipment builder manual for final lubrication recommendations or consult your Mobil™ Industrial Lubricants team for additional products.

NOT TO SCALE

NOT TO SCALE