Lubricants for machine tools

-

Mobil Vactra™ Oil No. Series

Premium-quality slideway lubricants designed to meet the requirements for accuracy, cutting fluid separability, and equipment protection

Mobil Velocite™ No. Series

Premium performance products primarily designed for the lubrication of high-speed spindles in machine tools

Mobilmet™ 440 Series

Neat cutting fluids (chlorine-free) for a very wide variety of non-corrosive cutting & machining operations from moderate to severe ones

-

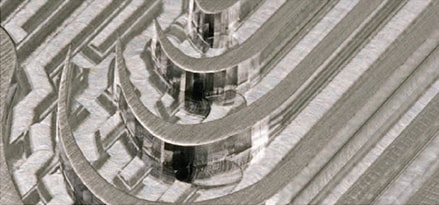

MOBIL™ VACTRA SLIDEWAY SERIES

Mobil™ Vactra Slideway are high-quality slideway lubricants specifically designed for the lubrication of linear motion guides, ball screws and slideways of high precision machine tools and metal processing machines.

Mobilmet™ 420 Series

Chlorine-free, non-staining and non-corrosive neat cutting fluids. They are designed for light to moderate duty cutting operations

Mobilgrind

The Mobilgrind series of products are non-staining mineral oils intended for conventional and high speed grinding and honing applications across a wide range of materials and operations.

Services that advance your business

We have expert knowledge to support you every step of the way with your equipment servicing requirements.

Technical and useful resources

Handling Aqueous Metalworking Fluids

Get the do’s and don’ts to handling aqueous cutting fluids, as well as machine preparation and maintenance.

Slideway lubrication stick-slip effect

In a metal removal process, loss of frictional control can cause inaccuracies that ultimately result in lost machine tool productivity. Learn how to avoid this.

Chlorine-free neat cutting oils

Changes in machine design, health concerns and environmental awareness have affected the use of chlorinated oils and additives. Learn more about chlorine-free formulations.

Looking for additional applications?

Whatever your application, we have the products that you can rely on to help increase up-time and efficiency* across all your industrial equipment. Explore the solutions that help your equipment perform to it's optimum potential.

Explore more

Discover our range of synthetic and grease products

Increase uptime and efficiency* with the products you need, with our comprehensive range you can find the solution to your specific needs and challenges.

Discover more